What makes us

different

We have a passion for what we do, excellent service and support, innovative and consistantly producing quality work.

‘Why wouldn’t you choose Giorgio Dental?’

What makes us

different

We have a passion for what we do, excellent service and support, innovative and consistantly producing quality work.

‘Why wouldn’t you choose Giorgio Dental?’

Meet our founder,

George Thalassinos

I established Giorgio Dental in 1992 having been a licensed and qualified technician since 1980 and a laboratory owner since 1985.

Giorgio Dental is a family owned and operated business. As a family we are passionate about establishing and nurturing a sustainable Australian manufacturing business for generations to come.

Being an active director of a truly full-serviced laboratory, I feel that it is incumbent on me to continue to thirst for knowledge in all aspects of cosmetic and restorative dentistry. You can never stop learning. That mindset is vital to our team’s success.

Importantly, I love what I do, and do what I love – work with a dynamic team to produce World-class results for clinicians and their patients right here in Melbourne.

Giorgio began as a family-run business back in 1991, opening the current Coburg facility in 1996.

Since then, our modest little business has grown into the industry leader that it is today thanks to our innovation and excellence.

In 1992, George Thalassinos was a young father and master technician fresh from a stint as a part owner of a Laboratory in Melbourne’s CBD.

He started Giorgio Dental from home but being its sole employee didn’t stop him from dreaming.

The new Laboratory had to produce exceptional Dental Prosthesis and be at the forefront of Dental Technology with a personalised approach to customer service.

The fledgling Laboratory moved to its current HQ at 205-209 Moreland Road in 1995. In the time since, the Laboratory and its team have achieved a multitude of milestones.

These include the invention of the Giorgio Sectional Bridge® and the establishment of a Digital Workflows facility that rivals any in the World.

George’s sons, Ross and Sam have carried on the tradition from a technical, operational and strategic perspective with Ross joining in 1999 and Sam in 2007.

Ross has been a qualified technician for well over a decade.

Although trained as a traditional technician, he has an affinity with emerging technologies that tangibly improve treatment outcomes.

His passion for Innovation and Dentistry is evident in his body of work in various implementations in our Digital Workflows as well as getting the best out of our processes on a daily basis.

Our Director of Innovation, Sam, has a background in Marketing, Customer relations and Business Development.

Initially joining the team in 2007, he utilised these skills to engage with a wider and expanding customer base.

He has since broadened his focus to the identification and uptake of innovative equipment and practices that maintain Giorgio Dental’s status as a leading Laboratory.

Sam also liaises with various Government bodies to manage materials efficiency projects, Research and Development and training.

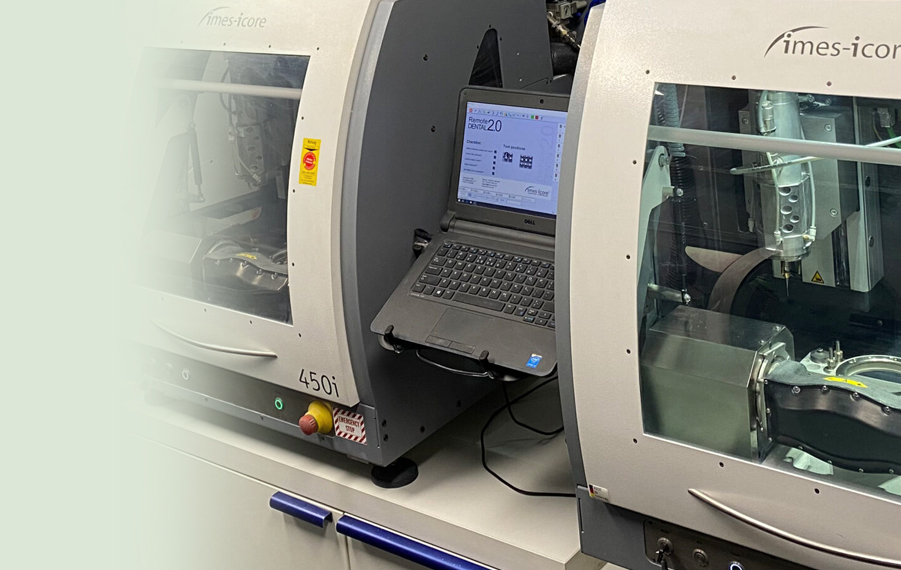

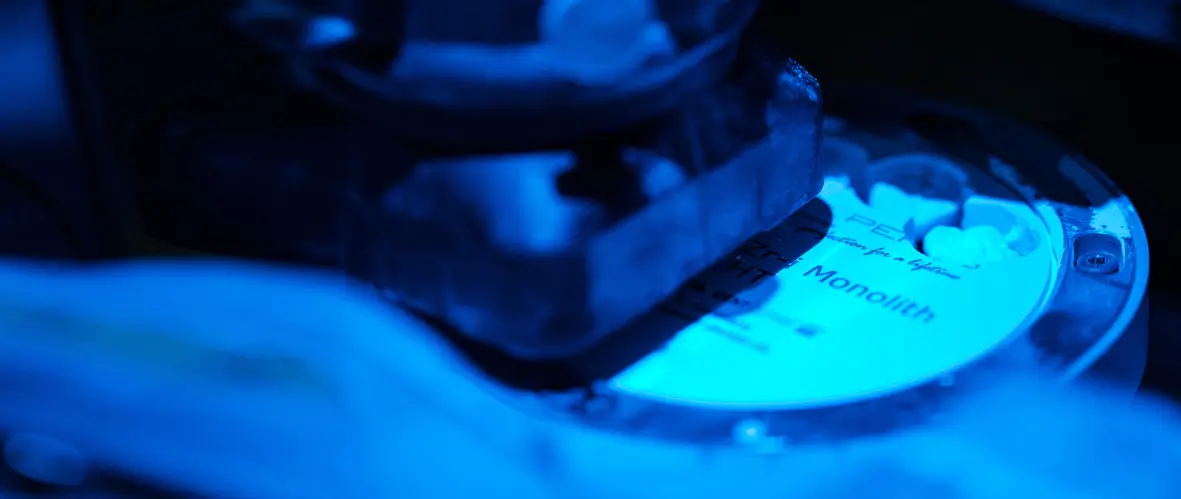

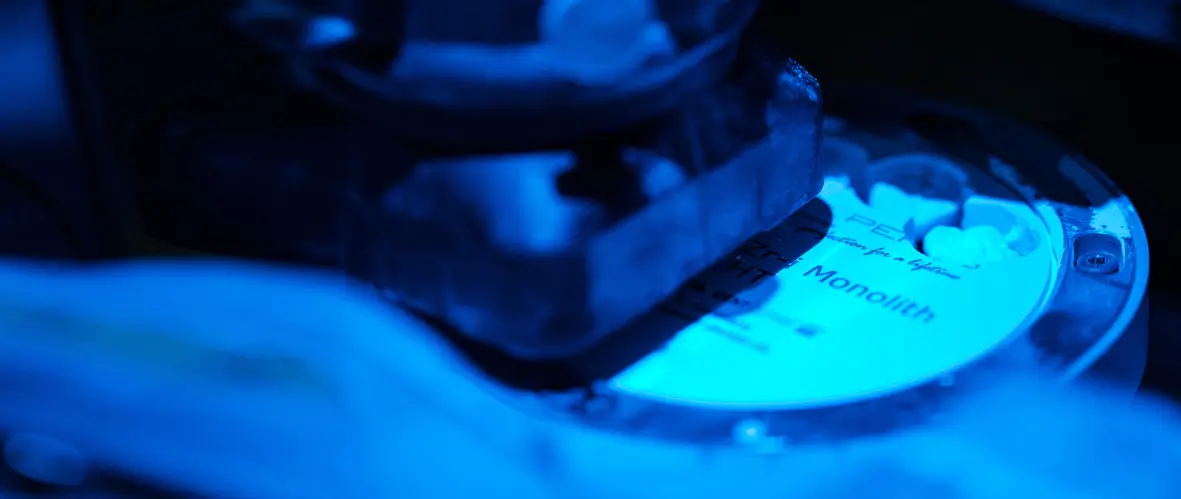

Giorgio Dental establishes an Innovation strategy investing heavily in Digital Workflows.

The Laboratory introduces emerging Digital Technology including 3D Printing and CAD-CAM systems.

This approach through sustainable practices is not only an Australian first but a world leading application of this technology.

Our efforts result in even better Prosthetics, drastically shortened turnaround times and profound material efficiencies including six tonnes of plaster waste reduction per annum.

In 2012, Giorgio Dental was chosen to operate the Laboratory within the Dental Faculty at Melbourne University in Carlton.

Here, the team services the Postgraduate Program and the University’s state-of-the-art clinic.

This follows on from George’s active participation in sponsoring Dental students for their final year since the establishment of the Laboratory in 1992.

Regular engagement with Universities and other training providers is seen as being central to the future of our business and the Industry as a whole.

The team is developing new 3D Printing materials including ceramics, various metals and acrylics to be applied to all areas of Dentistry.

Diagnostics, Orthodontic and Implant planning is further developed with the use of Augmented Reality and upgrades of scanning and CAD design.

Our effects on the environment continue to decrease dramatically with the use of less plaster, PVS and other material wastes.

Innovation preserves jobs, a family business is competitive on the world stage and this sustainable Australian business story continues for generations to come.

TBC

Meet the team

Together our highly qualified and experienced ceramists, design center and friendly admin team are empowered to take ownership of their tasks in the process to ensure that all cases that leave our laboratory do so meeting our high standards of quality.